If you need any help, please feel free to contact us

Product Series

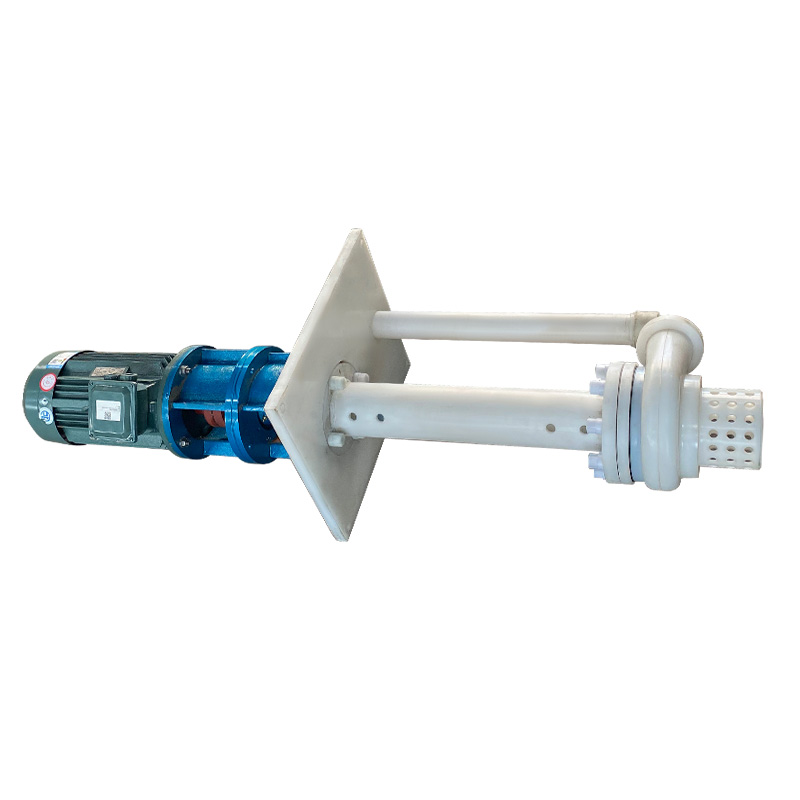

Fluoroplastic Anti-Corrosion Centrifugal Pump Manufacturers

About Us

News

-

Industry News 2026-02-09

In the complex and safety-critical world of industrial fluid handling, the choice of pumping technology is not merely a matter of moving liquids from point A to...

View More -

Industry News 2026-02-02

Introduction: The Workhorse of Industrial Fluid Transport In the vast network of industrial processes, from chemical manufacturing and agricultural irrigation t...

View More -

Industry News 2026-01-27

Selecting high-performance pumping equipment requires a deep understanding of fluid mechanics and material compatibility. The flowmore horizontal pump is a stap...

View More -

Industry News 2026-01-22

In industrial, agricultural, and municipal applications, selecting a reliable high‑performance submersible pump is critical for operational continuity, energy e...

View More

Contact us now

Industry Knowledge Extension

How does Jiangsu Huanyu Chemical New Materials Co., Ltd., a professional manufacturer of fluoroplastic anti-corrosion centrifugal pumps, lead industry innovation?

In the field of chemical industry, the corrosion resistance and efficiency of equipment are key factors in enterprise production. Fluoroplastic anti-corrosion centrifugal pumps are ideal for handling corrosive media, and their performance and quality are directly related to the stability and safety of the production line. Jiangsu Huanyu Chemical New Materials Co., Ltd., as a leader in this field, has been committed to the research and development and manufacturing of fluoroplastic anti-corrosion centrifugal pumps since its establishment in 1987, and has won wide recognition in the market with its professional technology and excellent quality.

Jiangsu Huanyu Chemical New Materials Co., Ltd. has more than 100 employees, integrating machinery manufacturing, hot and cold processing, and investment casting, forming a complete and efficient industrial chain. The company continues to innovate, and the existing fluoroplastic anti-corrosion centrifugal pump products have covered more than ten series and more than 300 specifications, which can meet the needs of different industries and different working conditions. These pump bodies are made of a variety of alloy materials, with excellent corrosion resistance, high temperature resistance and wear resistance, ensuring stable operation in various harsh environments.

In terms of production, Jiangsu Huanyu Chemical New Materials Co., Ltd. is equipped with complete production equipment, including advanced CNC machine tools, machining centers, etc., to ensure the accuracy and efficiency of product processing. At the same time, the company also has physical and chemical laboratories and testing equipment to conduct strict quality inspections on raw materials and finished products to ensure that every fluoroplastic anti-corrosion centrifugal pump shipped meets international standards and foreign advanced standards.

It is worth mentioning that the company also has a pump performance testing center that can conduct comprehensive and accurate tests on the performance of fluoroplastic anti-corrosion centrifugal pumps. This move not only improves the reliability and stability of the product, but also provides customers with more detailed and accurate product performance data to help customers better choose and use products.

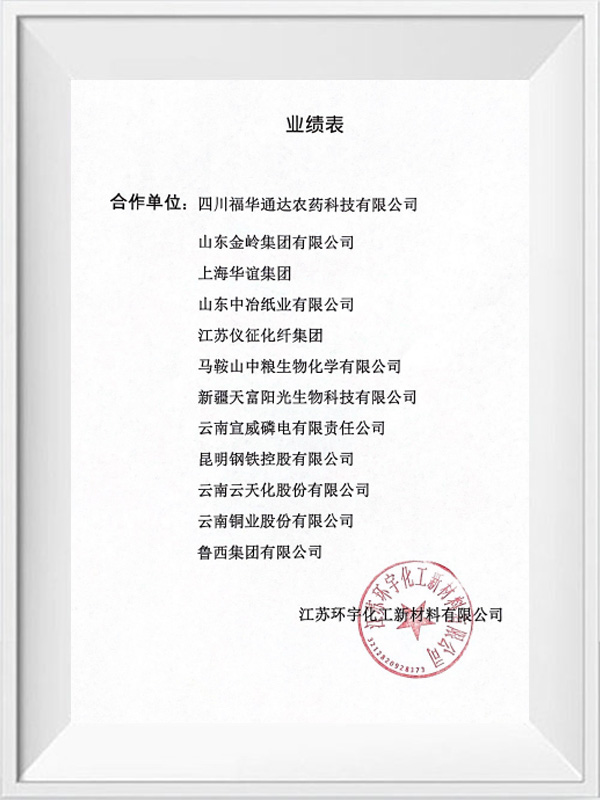

Jiangsu Huanyu Chemical New Materials Co., Ltd.'s fluoroplastic anti-corrosion centrifugal pumps are widely used in many fields such as petroleum, chemical, pharmaceutical, electroplating, environmental protection, etc., and their outstanding performance and quality have been unanimously praised by customers. The company always adheres to customer-centricity, quality as life, innovation as the driving force, and continuously improves its own technical strength and service level to provide customers with better quality and efficient products and services.

In the future, Jiangsu Huanyu Chemical New Materials Co., Ltd. will continue to uphold the corporate spirit of "professionalism, innovation, integrity and win-win", devote itself to the research and development and manufacturing of fluoroplastic anti-corrosion centrifugal pumps, and contribute more wisdom and strength to the development of the chemical industry.

English

English русский

русский Español

Español