If you need any help, please feel free to contact us

Product Series

Vertical Industrial Axial Flow Pump Manufacturers

About Us

News

-

Industry News 2026-02-09

In the complex and safety-critical world of industrial fluid handling, the choice of pumping technology is not merely a matter of moving liquids from point A to...

View More -

Industry News 2026-02-02

Introduction: The Workhorse of Industrial Fluid Transport In the vast network of industrial processes, from chemical manufacturing and agricultural irrigation t...

View More -

Industry News 2026-01-27

Selecting high-performance pumping equipment requires a deep understanding of fluid mechanics and material compatibility. The flowmore horizontal pump is a stap...

View More -

Industry News 2026-01-22

In industrial, agricultural, and municipal applications, selecting a reliable high‑performance submersible pump is critical for operational continuity, energy e...

View More

Contact us now

Industry Knowledge Extension

What are the mechanical seal design and materials of the vertical industrial axial flow pump? How to ensure the reliability and durability of the seal?

The design of the mechanical seal of the axial flow pump is one of the keys to ensure its performance. Mechanical seal refers to a device in which two sealing elements fit each other on a smooth and straight surface perpendicular to the axis and rotate relative to each other to form a seal. Huanyu's axial flow pump mechanical seal design adopts advanced structure and technology to ensure the reliability and durability of the seal.

Sealing end face design: The sealing end face composed of the dynamic ring and static ring of the mechanical seal is the key to the sealing effect. Huanyu uses high-precision processing technology to ensure the smoothness and flatness of the sealing end face to reduce friction and wear and improve sealing performance. At the same time, the dynamic ring can move axially for compensation to ensure that the sealing end face is always well fitted.

Elastic element design: The elastic element is a buffer compensation mechanism in the mechanical seal, which plays a role in compensating for the wear of the sealing end face and adapting to axial movement. Huanyu uses high-quality elastic elements, such as springs or bellows, to ensure that they have good elasticity and durability.

Auxiliary sealing ring design: Auxiliary sealing ring is an important component of mechanical seal, which plays a role in preventing medium leakage and lubricating the sealing end face. Huanyu Company selected suitable sealing ring materials, such as O-rings, V-rings, etc., and ensured their dimensional accuracy and surface quality.

The material selection of axial flow pump mechanical seal has an important influence on its performance and durability. Huanyu Company carefully selected suitable sealing materials according to the properties of the medium and working conditions to ensure the reliability and durability of the seal.

Material of dynamic ring and static ring: Dynamic ring and static ring are one of the most critical components in mechanical seal. Huanyu Company selected high-strength, corrosion-resistant and wear-resistant materials such as silicon carbide, ceramics, cemented carbide, etc. according to the corrosiveness, temperature, pressure and other factors of the medium. These materials have excellent mechanical properties and chemical stability, and can adapt to various harsh working conditions.

Silicon carbide: It has the advantages of high hardness, high strength, wear resistance, corrosion resistance and high temperature resistance, can adapt to different working conditions, and has broad application prospects.

Ceramics: It has high hardness, high strength, good wear resistance, corrosion resistance and high temperature resistance. Its main advantage lies in its excellent wear resistance and high temperature resistance.

Cemented carbide: A hard material composed of tungsten, cobalt, titanium and other elements, which has high hardness, high strength, wear resistance, corrosion resistance and high temperature resistance, and is widely used in pump mechanical seals.

Elastic element material: The material selection of elastic elements has an important influence on their elasticity and durability. Huanyu Company uses high-quality spring steel or stainless steel and other materials to make elastic elements to ensure that they have good elasticity and corrosion resistance.

Auxiliary sealing ring material: The material selection of auxiliary sealing rings needs to be considered according to factors such as the nature and temperature of the medium. Huanyu Company uses suitable rubber, polytetrafluoroethylene and other materials to make auxiliary sealing rings to ensure that they have good sealing performance and aging resistance.

In order to ensure the reliability and durability of vertical industrial axial flow pump mechanical seals, Huanyu Company has taken a series of effective measures:

Optimize the sealing structure: Improve the adaptability and stability of the seal by optimizing the shape and size of the sealing end face and improving the design of the elastic element.

Select high-quality materials: As mentioned above, Huanyu Company carefully selects suitable sealing materials according to the properties of the medium and working conditions to ensure the reliability and durability of the seal.

Strictly control processing accuracy: Use high-precision processing equipment and processes to strictly control the processing accuracy and surface quality of sealing components to reduce friction and wear and improve sealing performance.

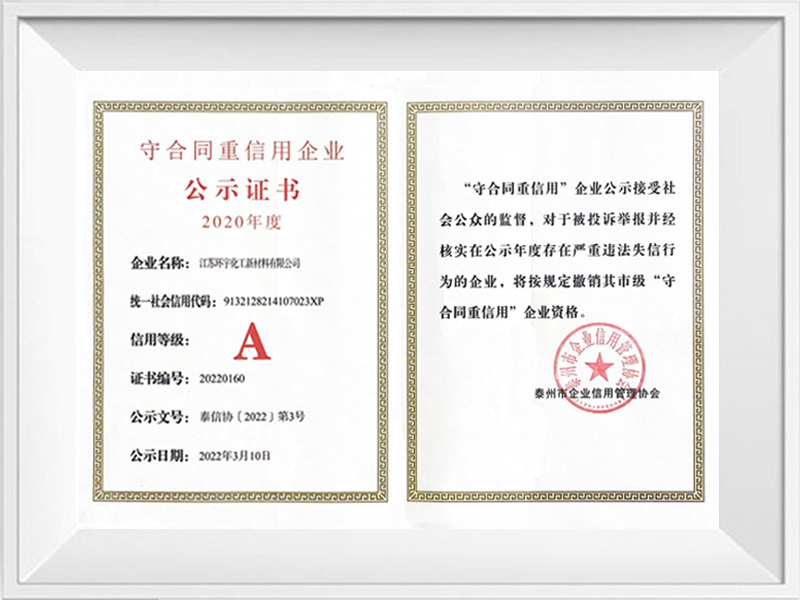

Strengthen quality inspection and testing: Huanyu Company has a pump performance testing center to conduct strict quality inspection and testing on the axial flow pump products produced, including sealing performance tests, pressure resistance tests, etc., to ensure that the quality and performance of the products meet the standard requirements.

Provide high-quality after-sales service: Huanyu Company provides customers with high-quality after-sales service, including installation and commissioning, repair and maintenance, etc., to ensure the normal operation and long-term use of axial flow pump products.

English

English русский

русский Español

Español