In high-stakes industrial environments, the transport of toxic, corrosive, or flammable fluids demands a pumping solution that guarantees zero leakage. The Chemical Magnetic Drive Pump has emerged as the engineering standard for these applications, utilizing a sealless design that eliminates the traditional "weak link" of mechanical seals. For facility engineers and procurement specialists, adhering to rigorous safety standards is not merely a regulatory requirement but a fundamental strategy to prevent catastrophic environmental incidents and ensure personnel safety.

Hermetic Isolation: The Sealless Advantage for Hazardous Fluids

The primary safety feature of a magnetic drive system is its hermetic isolation. By replacing mechanical seals with a static containment shell, a sealless chemical magnetic drive pump for hazardous fluids provides a physical barrier that prevents volatile organic compounds (VOCs) and toxic vapors from escaping into the atmosphere. According to the latest technical directives from the Hydraulic Institute, sealless technology is now recommended as the primary containment method for Class I hazardous liquids due to its ability to mitigate fugitive emissions that traditional sealed pumps cannot effectively control.

Source: Hydraulic Institute - Performance Standards for Sealless Pumps

While mechanical seal pumps rely on a thin film of fluid to lubricate moving parts—creating a persistent risk of leakage if the seal fails—the magnetic drive variant utilizes a static containment shell that remains completely airtight, even during power surges.

| Design Feature | Traditional Mechanical Seal Pump | Sealless Chemical Magnetic Drive Pump |

| Sealing Type | Dynamic (Moving parts) | Static (Stationary shell) |

| Emission Risk | Moderate to High (Seal wear) | Zero (Hermetically sealed) |

| Hazardous Suitability | Requires secondary containment | Naturally contained design |

Material Integrity: Engineering for Extreme Corrosion

Safety is intrinsically linked to material compatibility. Reviewing corrosion resistant chemical magnetic drive pump specifications is critical when handling aggressive acids like concentrated sulfuric acid or sodium hypochlorite. Engineers must verify that wetted parts—such as the impeller, inner magnet assembly, and containment shell—are constructed from high-purity fluoropolymers (PVDF/ETFE) or specialized alloys. According to the 2024-2025 Global Chemical Equipment Market Analysis, the industry has seen a 15% increase in the adoption of carbon-fiber-reinforced containment shells, which offer superior burst pressure resistance compared to standard plastic liners.

Source: Grand View Research - Chemical Processing Equipment Market Insights 2025

Advanced Monitoring: Preventing Dry Running and Overheating

Thermal management is the cornerstone of safe pump operation. A high temperature chemical magnetic drive pump for industrial use must be equipped with secondary safety controls, such as power monitors or temperature sensors on the containment shell. Because these pumps rely on the pumped fluid for cooling the internal bearings, "dry running" can cause rapid heat buildup and magnet demagnetization. Modern safety standards for 2026 emphasize the integration of "Intelligent Monitoring" systems that can automatically trip the motor if temperature fluctuations exceed 5% of the operational baseline.

Conventional pumps may continue to operate during minor cavitations, but high-temperature magnetic drive systems require precision sensors to prevent magnet decoupling, which could otherwise lead to structural deformation of the containment shell.

| Monitoring Variable | Standard Industrial Pump | High Temperature Mag-Drive Pump |

| Thermal Safety | Manual/External Check | Integrated Shell Temperature Sensors |

| Dry Run Protection | External Flow Meter | Active Power Monitoring/Automatic Trip |

| Magnet Stability | N/A | Rare-earth High-Coercivity Magnets |

Lifecycle Economics: Maintenance and Reliability

When evaluating a chemical magnetic drive pump maintenance cost vs mechanical seal, the long-term ROI favors the sealless design. Mechanical seals are the most common cause of pump failure, requiring expensive seal flush systems and frequent downtime for replacement. In contrast, a magnetic drive pump has fewer wearing parts, primarily requiring periodic inspection of the bushings and thrust rings. This simplified architecture not only lowers the wholesale chemical magnetic drive pump price for water treatment over the equipment's lifespan but also reduces the likelihood of "maintenance-induced" leaks that often occur during complex seal repairs.

Unlike sealed pumps that require costly peripheral support systems (like API Plan 52/53), magnetic drive pumps are self-contained units that require significantly fewer spare parts and less specialized labor for routine upkeep.

| Maintenance Factor | Mechanical Seal System | Chemical Magnetic Drive Pump |

| Mean Time Between Failure | Low to Moderate | Very High |

| External Flush System | Mandatory (Increases complexity) | Not Required (Self-cooling) |

| Estimated Labor Cost | High (Specialized seal setting) | Low (Modular component swap) |

About Our Manufacturing Excellence

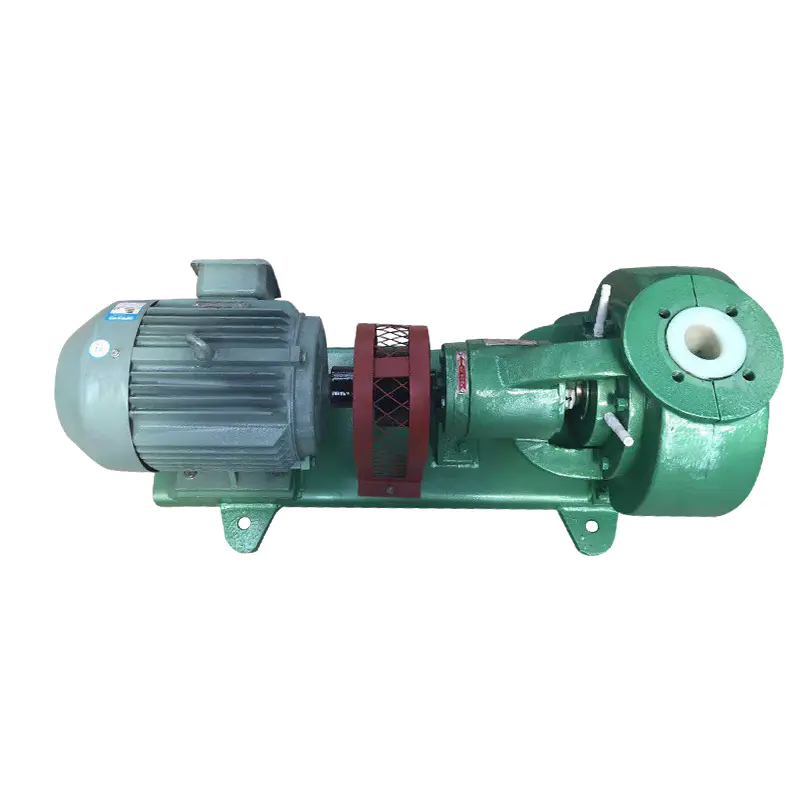

Our company is a premier global provider of fluid handling solutions, specializing in the precision engineering of the Chemical Magnetic Drive Pump. We utilize state-of-the-art CNC machining and high-purity fluoropolymer molding to ensure that every pump meets ISO 2858 and ASME B73.3 standards. Our 2026 product line features integrated thermal monitoring and carbon fiber reinforced containment shells, providing unmatched safety and efficiency for hazardous chemical transfer. By partnering with us, industrial clients receive not just a pump, but a certified containment solution designed to withstand the most aggressive chemical environments in the world.

Frequently Asked Questions (FAQ)

1. Why is a sealless design safer for hazardous fluids?

Utilizing a sealless chemical magnetic drive pump for hazardous fluids eliminates the dynamic seal, which is the most frequent point of leakage in industrial pumps. This creates a completely enclosed system that prevents toxic leaks into the workspace.

2. How do material specifications prevent pump failure?

Checking corrosion resistant chemical magnetic drive pump specifications ensures the materials can withstand the specific pH and concentration of your fluid, preventing internal erosion that could lead to a containment breach.

3. Is a magnetic drive pump more expensive to maintain?

When looking at chemical magnetic drive pump maintenance cost vs mechanical seal, the mag-drive pump is significantly cheaper over its life. It avoids the costs of seal replacements and the external water or oil systems required to support them.

4. Can magnetic drive pumps handle high-temperature fluids?

Yes, a specialized high temperature chemical magnetic drive pump for industrial use can handle fluids up to 250°C (482°F) or higher, provided it uses rare-earth magnets that maintain their strength at elevated temperatures.

5. How does the price affect water treatment projects?

The wholesale chemical magnetic drive pump price for water treatment is often offset by the reduction in chemical waste and environmental fines. These pumps are ideal for sodium hypochlorite and ferric chloride, which are notorious for destroying mechanical seals.

English

English русский

русский Español

Español