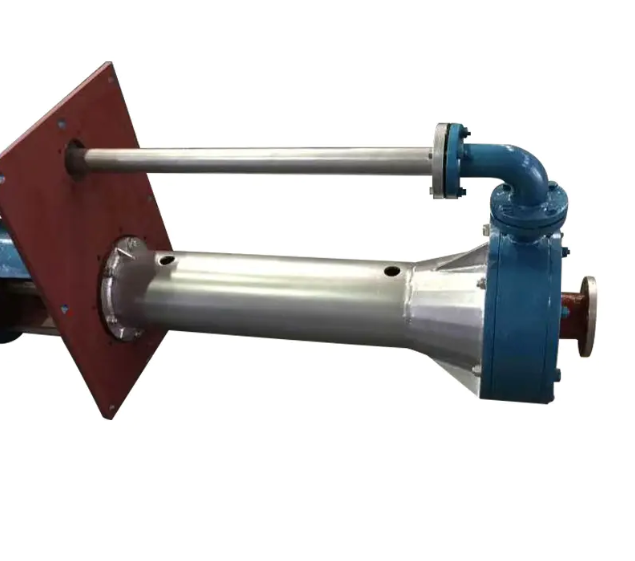

1: Combatting Wear and Tear: How Slurry Pump Design Tackles Extreme Abrasion in Mining Environments

1.1: Slurry Flow Carries Abrasive Particles That Accelerate Pump Wear

In mining operations, slurry is a mixture of water, ore fragments, and chemical reagents that can severely wear down pumping equipment. Solid particles in the slurry are typically hard and abrasive, and their constant interaction with the pump interior leads to accelerated surface degradation. Conventional pumps often fail under these harsh conditions, resulting in downtime, costly repairs, and reduced productivity.

1.2: High-Performance Materials Enhance Wear Resistance and Extend Service Life

To address this issue, Slurry Pumps are manufactured using ultra-durable materials such as hardened alloy steel, high-chrome cast iron, and synthetic rubber linings. These components are engineered to withstand the prolonged impact of abrasive particles without rapid erosion. This material choice significantly extends equipment lifespan and reduces the need for frequent maintenance or replacement.

1.3: Targeted Protection of Key Components Prevents Operational Failures

Special attention is paid to the pump’s most vulnerable parts, especially the impeller, which faces direct and constant contact with slurry particles. By using composite or high-chrome alloys, the impeller maintains structural integrity under stress. Additionally, internal liners protect the pump casing and reduce metal exposure, ensuring the system remains operational and reliable even during high-load, continuous-duty cycles.

2: Resisting Corrosion: Slurry Pumps Built for Harsh Chemical Exposure in Mining

2.1: Chemical Composition of Slurry Poses Severe Corrosive Risks

Slurries don’t just wear pumps down physically—they often contain corrosive agents like acids, alkalis, and other chemical reagents. These substances can react with the metal surfaces of pumps, causing pitting, rust, and structural degradation that leads to leaks or mechanical failure. Inconsistent chemical profiles across mining sites further complicate equipment selection.

2.2: Advanced Anti-Corrosion Materials Strengthen Structural Longevity

Slurry Pumps integrate corrosion-resistant materials such as stainless steel, duplex alloys, and special polymer coatings that protect against chemical attacks. These materials shield the pump’s metal components from corrosive environments, allowing them to perform reliably across a wide range of pH levels and slurry compositions. The result is a durable pump that resists both chemical and mechanical deterioration.

2.3: Reinforced Sealing Systems Minimize Leaks and Maximize Safety

To complement corrosion resistance, the Slurry Pump features robust sealing systems crafted from chemically stable materials. These seals prevent slurry leakage, enhance environmental safety, and reduce the risk of internal contamination or equipment breakdown. Such sealing technology is crucial in maintaining consistent system pressure and operational integrity in aggressive operating environments.

3: Efficiency Meets Durability: How Slurry Pump Engineering Reduces Operational Costs

3.1: Optimized Flow Channel Design Enhances Hydraulic Efficiency

Beyond wear and corrosion resistance, Slurry Pumps are designed for efficient operation in high-density slurry transport. Internal flow paths are streamlined to reduce turbulence and flow obstruction. This engineering reduces energy consumption, improves hydraulic performance, and ensures that slurry moves through the pump with minimal resistance and reduced power loss.

3.2: Structural Stability Minimizes Vibration and Mechanical Fatigue

The robust frame and vibration-resistant design of the Slurry Pump ensure low-noise, low-vibration operation, even under extreme flow and pressure conditions. Reinforced housing, balanced impeller design, and precise machining contribute to structural integrity, reducing fatigue-related failures and extending the machine’s operational window in heavy-duty applications.

3.3: Lower Maintenance Frequency Yields Long-Term Cost Advantages

Thanks to its wear-resistant materials, corrosion-proof design, and hydraulic efficiency, the Slurry Pump drastically lowers maintenance frequency and costs. Mining operations benefit from fewer production interruptions, minimized replacement part needs, and less labor associated with pump upkeep. This long-term reliability translates into significantly improved return on investment and reduced total cost of ownership.

English

English русский

русский Español

Español