High Temperature and High Pressure: The Harsh Challenges for Petrochemical Process Pumps

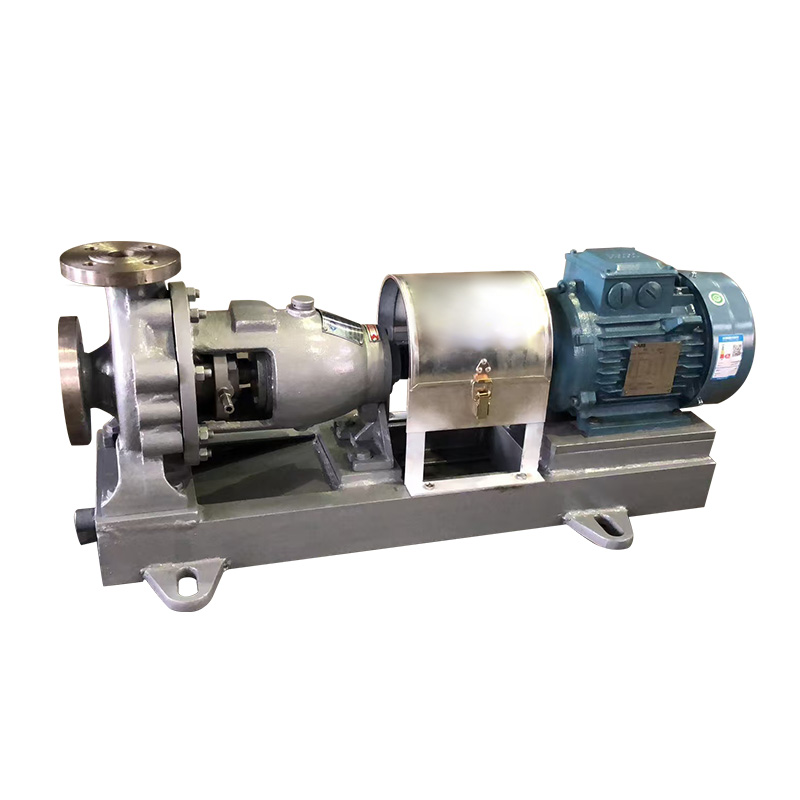

In the complex production processes of the petrochemical industry, pumps play a pivotal role, responsible for transferring a wide range of media, from room-temperature liquids to corrosive chemicals at high temperatures and pressures. The environment that petrochemical process pumps face is far more severe than that of general industrial pumps. They must operate stably under extreme conditions of hundreds of degrees Celsius and tens or even hundreds of atmospheres of pressure. These harsh conditions place exceptionally high demands on the pump’s structural design, material properties, and manufacturing processes. High temperatures can cause metal components to expand and deform, affecting the clearance between moving and stationary parts and potentially leading to a rotor seizure. High pressure, meanwhile, tests the strength and sealing integrity of the pump casing, shaft seals, and connectors. Therefore, from the very beginning of their design, petrochemical process pumps must incorporate special structures, such as a double-casing design to handle thermal expansion and contraction, and be built with materials that possess excellent mechanical properties and thermal stability to ensure safe and reliable operation under the most extreme conditions.

The API 610 Standard: The Golden Rule of the Industry

To standardize the design, manufacturing, and performance of petrochemical process pumps, the American Petroleum Institute (API) established the API 610 standard, which has since become the golden rule for the global petrochemical industry. The API 610 standard sets out detailed and rigorous regulations for all aspects of a pump, including vibration, noise, bearing life, sealing systems, and material selection. It mandates that pumps must be designed with higher safety margins and reliability, capable of withstanding prolonged continuous operation without frequent maintenance. For instance, the standard has clear requirements for bearing life, ensuring that they can operate reliably even under extreme conditions. Petrochemical process pumps manufactured in compliance with the API 610 standard have their performance and reliability fully guaranteed, significantly reducing the risk of production shutdowns due to equipment failure and ensuring the continuity and safety of petrochemical processes. This is why they are trusted by users worldwide.

Mechanical Seals: The Key Technology for Leakage Control

In petrochemical process pumps, the media being transferred are often flammable, explosive, toxic, or corrosive, and even a minuscule leak can trigger a severe safety incident or environmental contamination. Thus, mechanical seal technology plays a critical role in these pumps. A mechanical seal serves as a crucial barrier between the pump shaft and the pump body. It works through a pair or multiple pairs of faces—one rotating and one stationary—that form a dynamic seal under the influence of fluid pressure and spring force. Based on different operating conditions, petrochemical pumps employ various mechanical seal arrangements, such as single, double, or tandem seals. Double mechanical seals typically introduce an external flush or barrier fluid to lubricate and cool the seal faces, creating an additional layer of safety to effectively prevent media from leaking out. The reliability of mechanical seal technology directly determines the safety and environmental integrity of a petrochemical plant and is one of the most important indicators of a pump’s performance.

Material Selection: The Fundamental Guarantee of Corrosion Resistance

The petrochemical industry involves a wide variety of media with complex properties, many of which are highly corrosive. This demands that the materials used for petrochemical process pumps must possess exceptional corrosion resistance. From the pump casing and impeller to the shaft and sealing components, all parts in contact with the media must be meticulously chosen. Common corrosion-resistant materials include stainless steel, duplex stainless steel, and more advanced alloys like Hastelloy and titanium alloys. For instance, when handling strong acids like sulfuric acid or nitric acid, stainless steel or specific alloy grades with proven resistance are required. When dealing with chloride-containing media, duplex stainless steel might be necessary to resist stress corrosion cracking. The selection of materials is not merely about choosing the most expensive option; it is a careful balancing act based on factors such as the media’s temperature, pressure, corrosivity, and the pump’s expected service life, aiming for the best economic outcome while ensuring safety and reliability.

Remote Monitoring: Enhancing the Intelligence of Equipment Management

In a modern, large-scale petrochemical plant, managing hundreds or even thousands of pumps running simultaneously presents a significant challenge. With the development of IoT and big data technology, remote monitoring and fault diagnosis systems have become a powerful tool for improving the management of petrochemical pumps. By installing vibration, temperature, and pressure sensors at key points on the pumps, real-time operational data can be transmitted to a central control room. Engineers can then remotely monitor the status of each pump and analyze data trends to predict potential failures in advance. For example, when bearing temperature or vibration data shows an abnormal fluctuation, the system automatically triggers an alarm, prompting maintenance personnel to perform an inspection. This minimizes unscheduled downtime. This intelligent management model not only improves equipment reliability and safety but also optimizes maintenance strategies, shifting from reactive repairs to proactive prevention, and significantly enhancing the overall efficiency of petrochemical production.

English

English русский

русский Español

Español